Heritage: Wartime naval guns made by city steel manufacturer

I recently came across some pictures of magic lantern slides in the Sheffied Telegraph’s sister paper The Star.

These fascinating glimpses of the past were intriguing, but then I realised one of them was related to my own research interest in armaments.

Advertisement

Hide AdAdvertisement

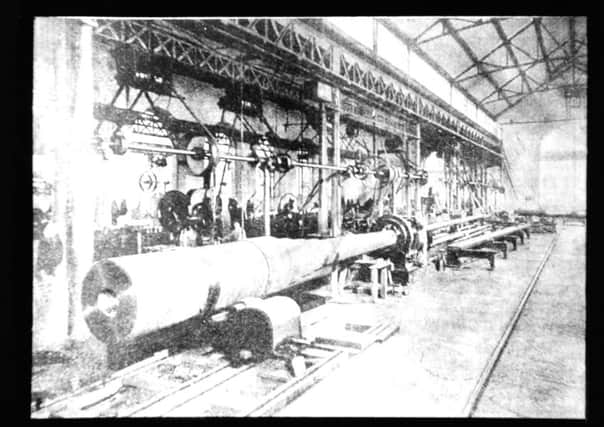

Hide AdThe image is undoubtedly of the Gun Shop at Vickers’ River Don Works, the modern-day site of Sheffield Forgemasters.

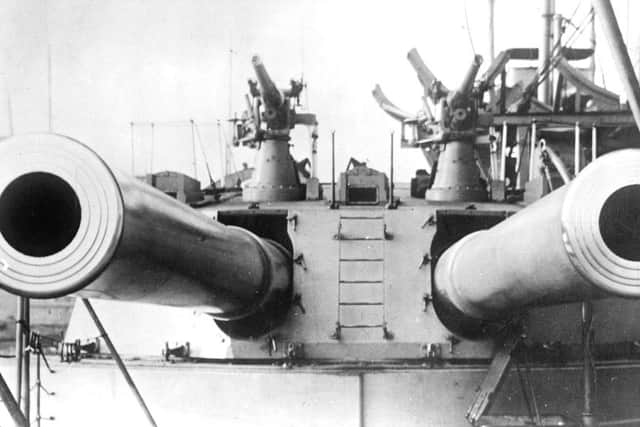

Vickers were the only one of the Sheffield armaments companies – which included the well-known names of John Brown, Cammell Laird, Thomas Firth and Hadfields – to produce finished naval guns for battleships.

The legacy of production endures too; a former Sheffield Forgemasters employee once told me that they still call one area of their works the Gun Shop.

The story of Vickers’ connection with armaments goes back to 1888 and the leadership of brothers Thomas and Albert Vickers.

Advertisement

Hide AdAdvertisement

Hide AdUnder their guidance, the company diversified into both armour and gun manufacture in Sheffield following a government initiative to widen manufacture of armaments products following the 1888 Naval Defence Act.

The company, then known as Vickers and Sons, continued to expand their connection with armaments and purchased a shipyard at Barrow (where the new Queen Elizabeth aircraft carrier has recently been built) and the Maxim machine gun works in 1897.

These moves brought with them a new name – Vickers, Sons and Maxim. The initials VS&M can still be seen in the building work of the former River Don Works on Brightside Lane.

In further expansion the company manufactured complete battleships, submarines and aircraft before the Great War.

In 1911 there was a name change to Vickers Ltd.

Gun manufacture was a complex and time-consuming process.

Advertisement

Hide AdAdvertisement

Hide AdFrom initial order to final delivery routinely took between two and three years.

The process commenced with the production of a nickel-chromium steel alloy, forged into three pieces, an inner tube, an outer tube and a cover.

Once forged, the three pieces would be machined to their specifications and the initial hole bored through the inner tube.

The outer tube would be heated and shrunk-fit around the inner tube, the two pieces then wrapped in around 100 miles of quarter-inch steel wire.

Advertisement

Hide AdAdvertisement

Hide AdThis process of manufacture strengthened the gun and protected it from recoil damage during firing.

Manufacture was completed with the cover, heat-shrunk over the wire to protect it from the elements.

The finished gun was then ready for the final hole cutting process, as depicted in the picture.

This giant piece of machinery was used to finish cutting the bore hole to the required diameter.

Advertisement

Hide AdAdvertisement

Hide AdGuns manufactured by Vickers were capable of firing 12-inch calibre shells, the size increasing before the Great War to 13.5 inch and finally 15 inch calibre for British battleships.

Vickers also manufactured guns for foreign battleships, including for the Spanish, Brazilian and Turkish navies.

After the hole was bored to size, the next stage of machining involved the cutting of rifling grooves.

These allowed the shells to rotate while being fired to keep them on target, and to perforate armour at speeds in excess of 1,000 miles per hour.

Advertisement

Hide AdAdvertisement

Hide AdThe cutting of rifling grooves was a very exacting process, which took a year to complete and could not be stopped once the process was started.

Any issues or imperfections in the process would result in the entire gun being dismantled and melted down, the whole time-consuming process of manufacture starting over.

The rifling was machined to a tolerance of 1/10,000th of an inch, thinner than the thickness of a human hair.

This was a highly advanced and exacting process at the limits of technological progress over 100 years ago.

Advertisement

Hide AdAdvertisement

Hide AdThe image is a clear reminder that in addition to the well known heritage of steel and cutlery in Sheffield, the city also had an important connection with armaments production.

At the outbreak of the Great War, Sheffield was undoubtedly the world centre of armaments production and technology.

Gun manufacture at Vickers’ River Don Works was just one part of a complex and intriguing story.

* Dr Chris Corker is a business historian who has been studying industry in Sheffield for over a decade.

Advertisement

Hide AdAdvertisement

Hide AdHe is a lecturer in management at The York Management School, and completed his PhD on the Sheffield armaments industry at Sheffield Hallam University in 2016.

His PhD work recently won the Coleman Prize awarded by the Association of Business Historians for excellence in new business history research.